Time:2025-06-25 Views:0

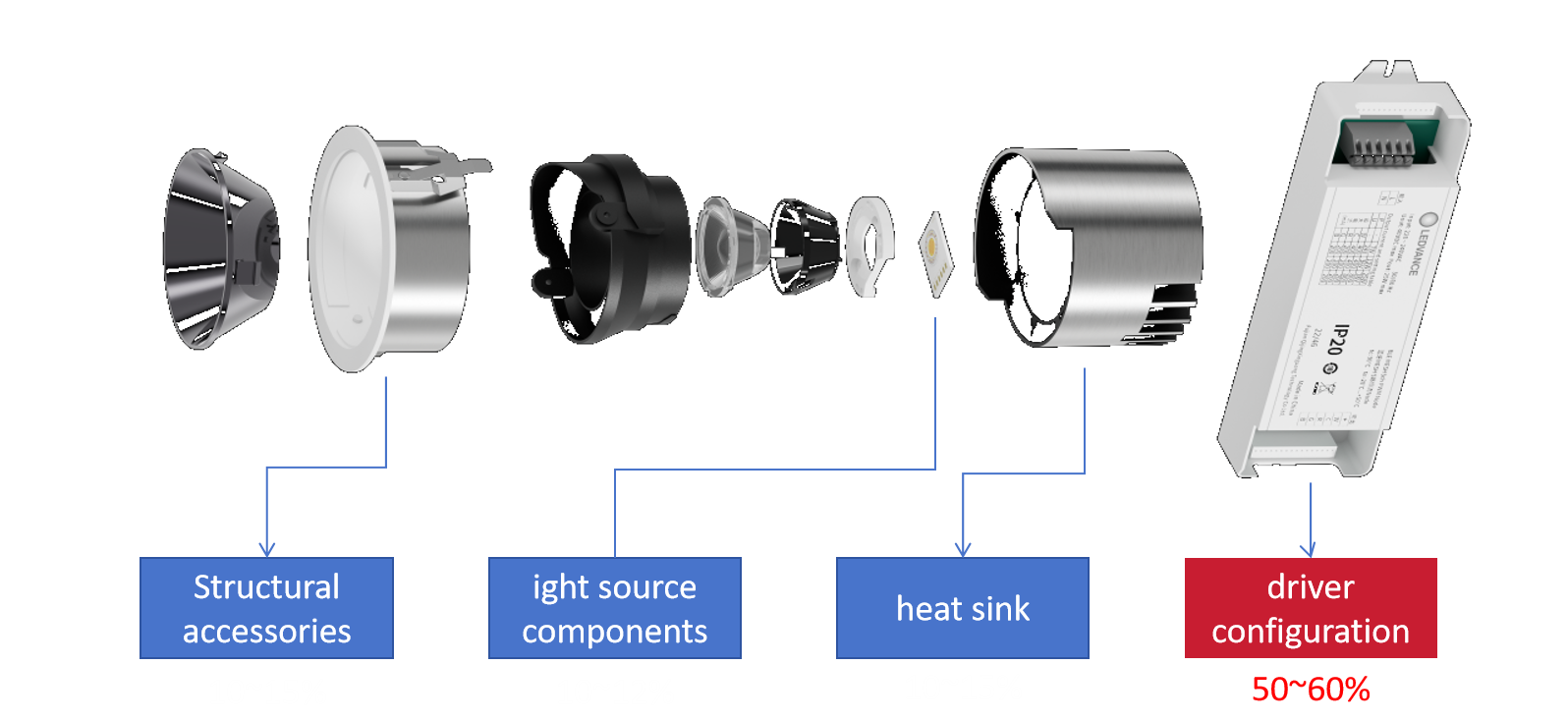

Cost Bottleneck of Lighting Fixtures >>>>>>>>>>>>>

China's lighting industry is going through a period of in-depth adjustment. The sales volume of the entire industry has shown a downward trend in both domestic and export markets. The continuous market contraction over the years indicates that the industry has officially entered an era of volume reduction. In the fierce inward competition, enterprises generally face the pressure of reducing costs and increasing efficiency. It is worth noting that domestic brands have a significantly higher proportion of investment in physical materials than international brands, and this difference in cost structure is becoming a key factor restricting the profitability of the industry.

Industry Status&Sales Costs

According to data from the China Association of Lighting Industry, the sales volume of China's lighting industry in 2023 was 600 billion yuan, a year-on-year decrease of 10.45%, marking the second consecutive year of decline.

The domestic sales scale reached 192 billion yuan, down 10.20% year-on-year, falling for four consecutive years.

The export sales scale stood at 56.3 billion US dollars, a year-on-year decrease of 6.10%, dropping for two consecutive years.

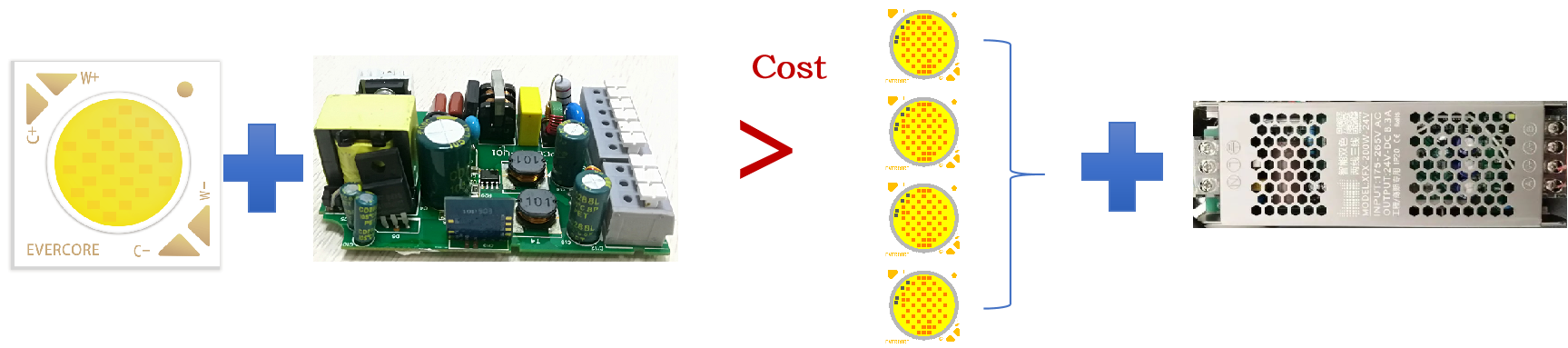

Constant-voltage COB light sources have reconstructed the power supply architecture of lighting systems through technological innovation, achieving full-chain cost optimization ranging from driving methods and compatibility to intelligent control. Their cost savings are not only reflected in hardware investment, but also in implicit advantages such as simplified installation and maintenance, and extended service life, providing the industry with an efficient and sustainable solution.

Professional analysis of technical characteristics:

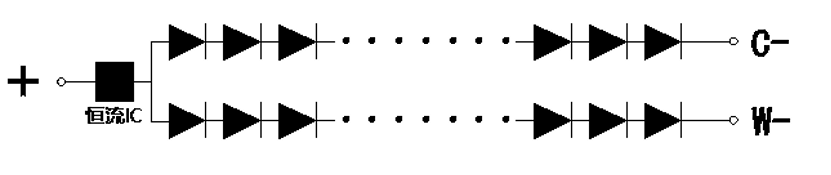

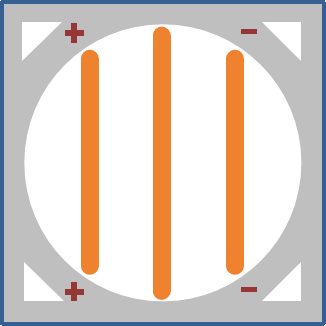

Evercore’s Constant Voltage COB light source achieves efficient and stable lighting solutions through innovative technology: Its technical core adopts a design where constant current ICs are connected in series at the positive terminal. By dynamically adjusting the current through multiple parallel ICs, it achieves precise current stabilization under constant voltage input. A single power supply can drive multiple groups of parallel-connected lamps, balancing light efficiency optimization and system cost savings, thus providing a cost-effective option for multi-scenario applications.

Principle of Constant Voltage Technology

A constant current IC is connected in series at the positive end of the light source, and multiple ICs are connected in parallel to change the current of the entire COB. The constant current IC stabilizes the current to achieve a constant voltage effect.

The maximum power consumption that a constant current IC can withstand is 1.2W, ensuring reliable operation of the constant current IC.

Characteristics of Constant Voltage Technology

Single white COB

● Adopting thermal deposition phosphor coating technology to effectively reduce the heat generation of COB light source

● Constant Voltage input, automatic constant current, safer and more convenient

Constant Current COB COB Constant Voltage COB

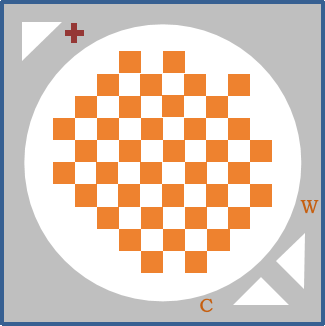

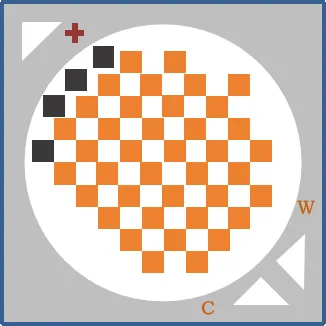

CCT Tunable Series:

● Adopting the latest chip level phosphor coating technology to achieve mosaic style uniform arrangement between different color temperatures;

● It is easier to achieve optical light distribution for lenses and reflectors, greatly reducing the design difficulty and cost of them;

●Multiple parallel-connected fixtures can be driven by a single driver to achieve group control.

![]()

Circular chip array Strip chip array Constant voltage mosaic chip array Constant current mosaic chip array

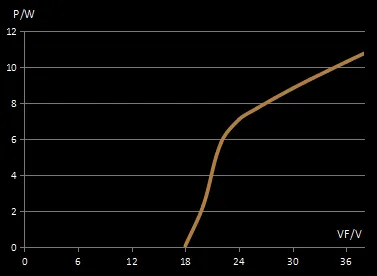

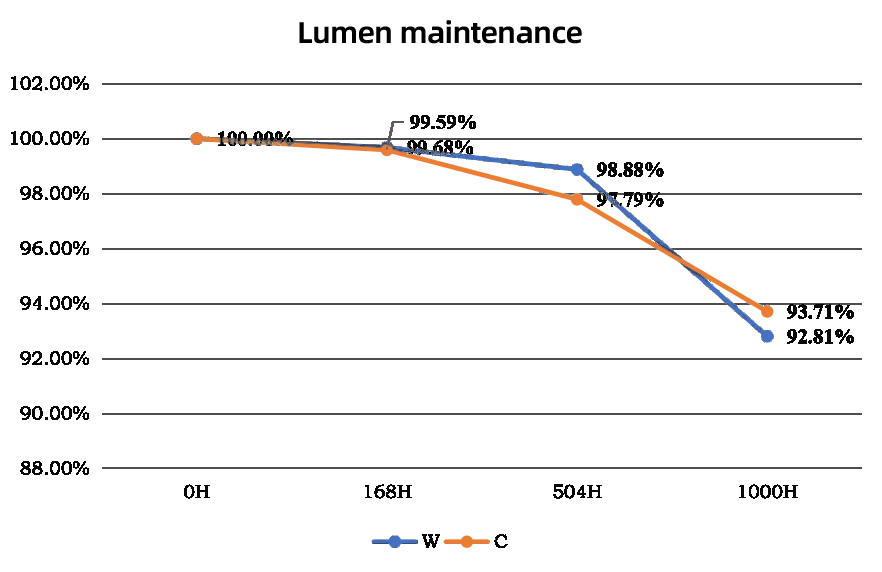

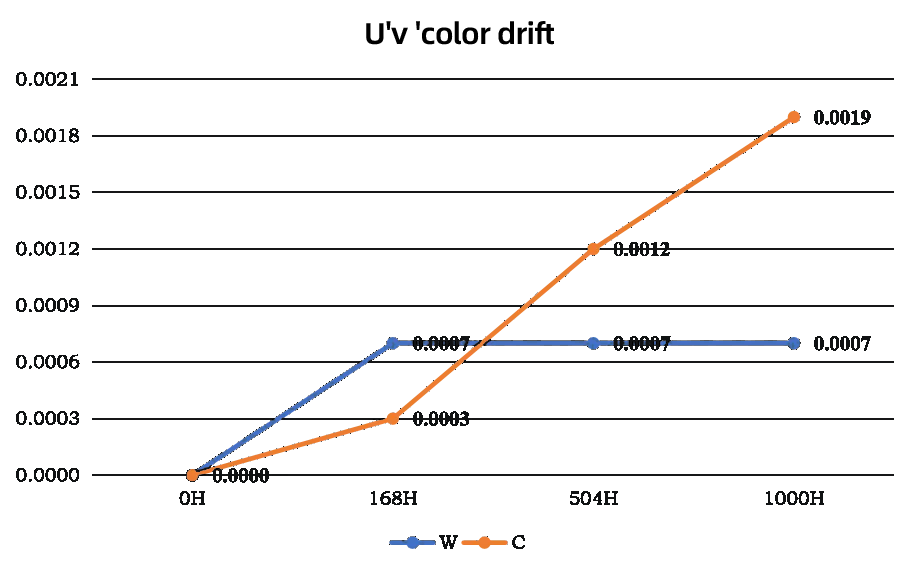

Product characteristic curve:

Vf-P Curve

●The voltage and power change curve reaches 24V/48V as the voltage increases, and the COB power reaches the typical power. As the voltage continues to rise, the power will also continue to increase, and the trend of change becomes smaller. The minimum operating voltage cannot be lower than 85%.

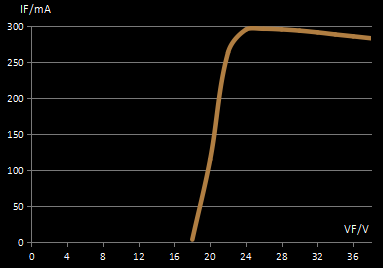

Vf-If Curve

●The voltage and current change curve reaches 24V/48V as the voltage increases, and the current reaches the typical current of IC driver. As the voltage continues to increase, the current change is not significant. The maximum working voltage cannot exceed 12.5%, and the maximum pulse voltage cannot exceed the typical voltage of 10V.

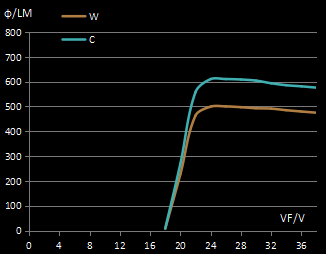

Vf-φ Curve

●The curve of voltage and luminous flux changes as the voltage increases to 24V/48V, and the luminous flux reaches a typical value. With the increase of voltage, the power of the IC increases, but the luminous flux changes little and the luminous efficiency decreases.

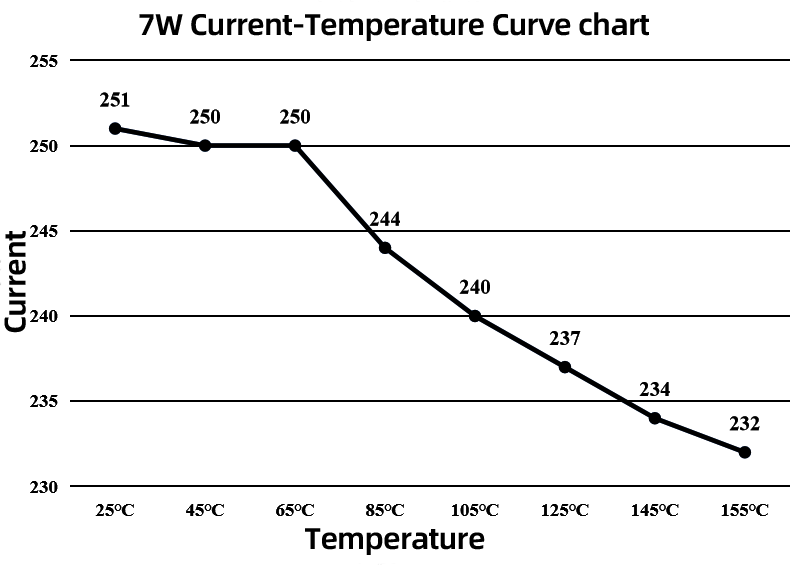

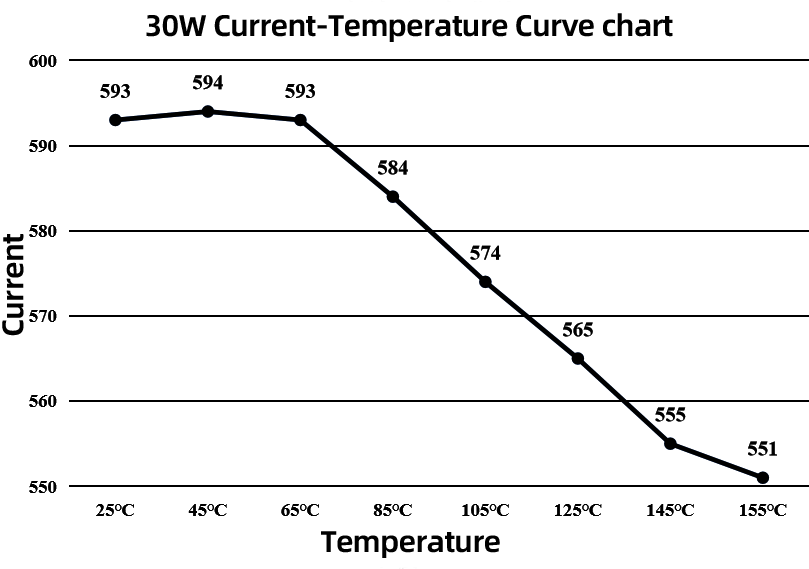

●Under normal working conditions (TC ≤ 65 ℃), as the temperature increases, the current of the product remains constant and almost does not decay

●When TC ≥ 65 ℃, the IC will automatically protectively reduce the current to avoid damaging the light source due to high temperature.

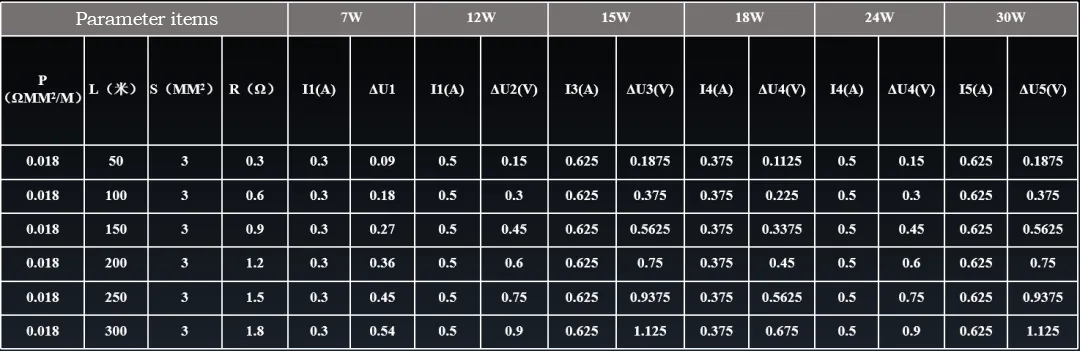

Voltage drop of centralized control line

Using 3 sqm copper wire,the maximum Voltage drop within 300m is less than 1.2V,and the over all lamp power drops by less than 1W.

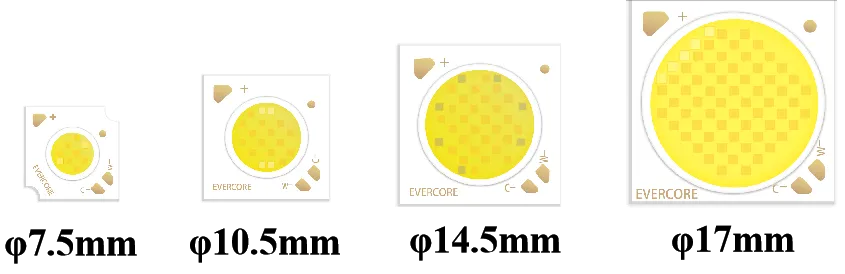

Product specification

HK Series (Dual-color CCT)

HK Series (Singal-color CCT)